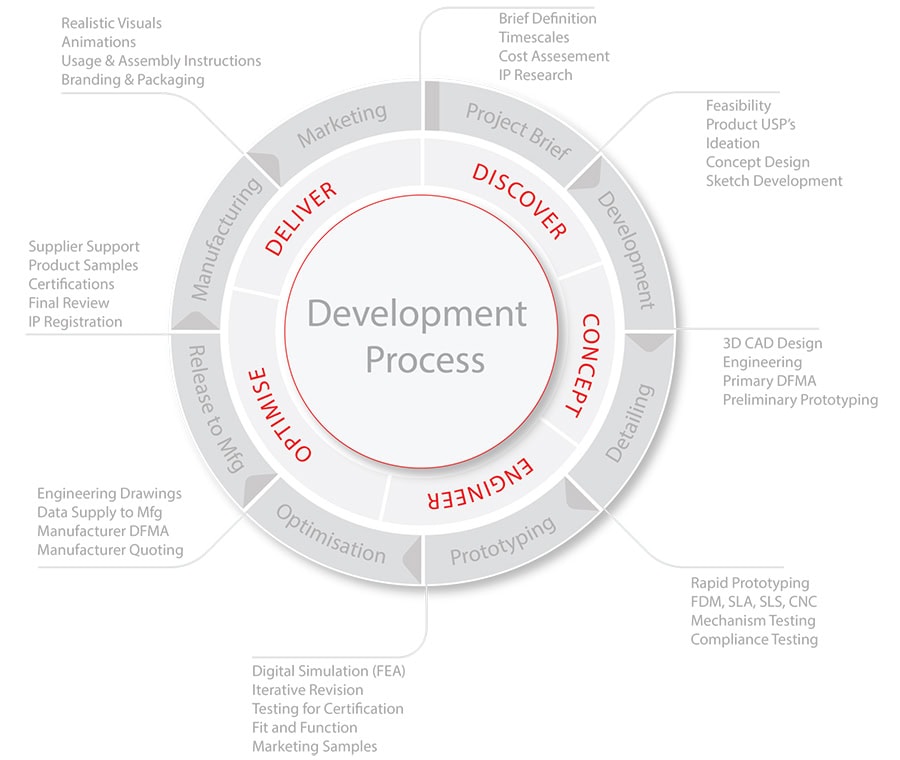

At Optima Design, we utilise a five-stage development process to ensure high-quality products are developed, with a clear and transparent workflow for our customers. Each stage is tailored to meet specific customer requirements, and we offer support at any stage of the cycle—from research to final product delivery and ongoing support. Whether clients need assistance with a single phase or full-cycle product development, we are equipped to handle it. The diagram below illustrates a typical full-cycle development process, highlighting how we guide clients through each step to deliver innovative, functional, and manufacturable products.